Product categories

Home > Product display > WC67K Torsion Axis Servo CNC press brake

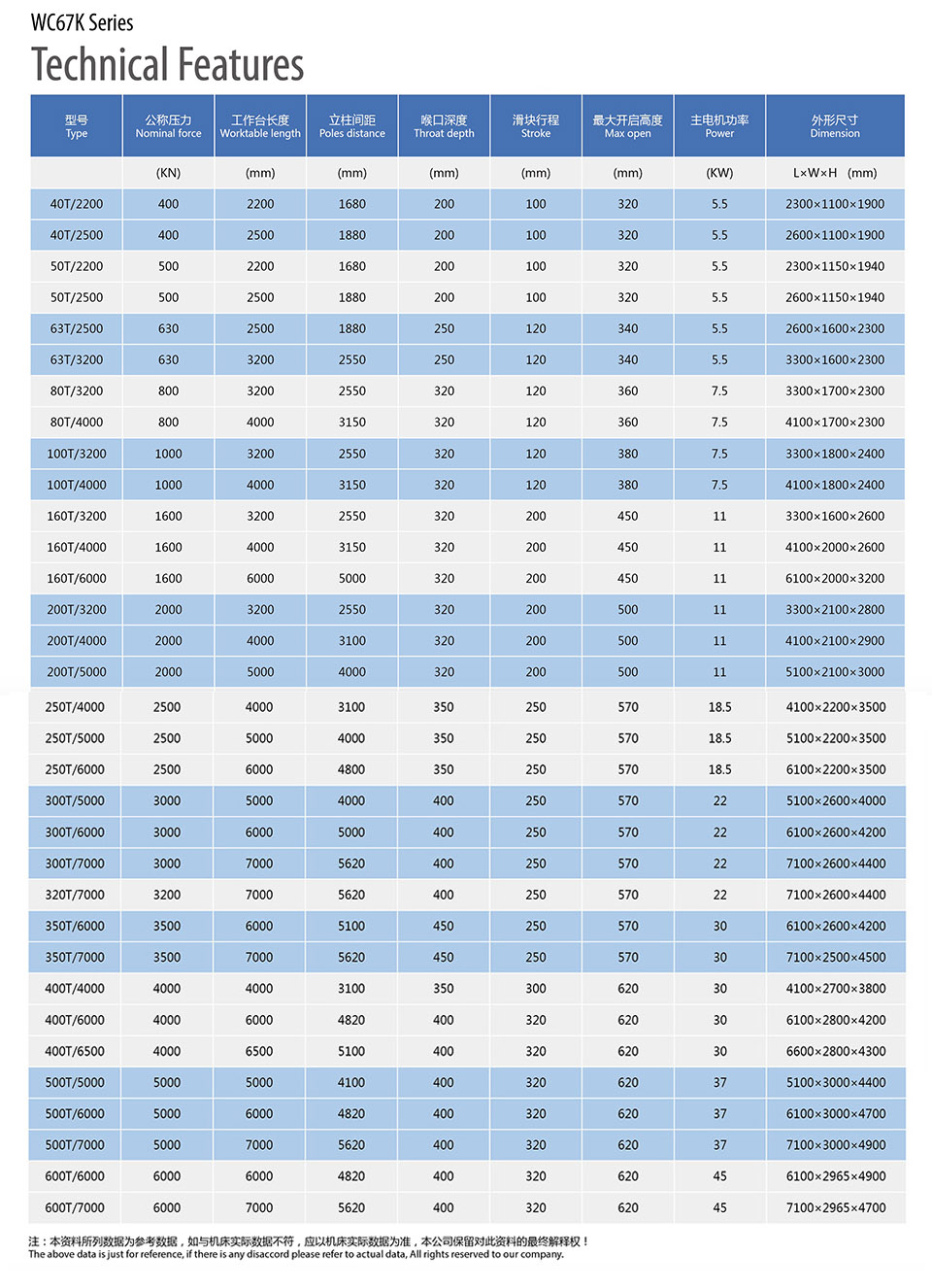

Main technical parameters

Nominal force: 1250kn

Table length: 4000mm

Worktable width: 180mm

Column spacing: 3100 mm

Throat depth: 400mm

Slider stroke: 120mm

Maximum opening height: 400mm

Slider stroke adjustment: 100 mm

Cylinder diameter: Ф 190mm

Main motor: Y132M-4 n = 1440r / min n = 7.5kw

Oil pump: nbt3-g16f

Slider speed: V working = 8mm / s, V return = 85mm / s, V empty = 10mm / S

System pressure: P = 24MPa

CNC system of back stop: snc52 (double axis servo CNC), tpi0s, CT8 (optional)

Thickness of left and right wallboards: 50mm

Slider thickness: 50mm

Thickness of vertical plate of worktable: 60mm

Dimension: l × w × H = 4600 × 1800 × 2600

Weight: 8.3 tons

Accessory Factory

Electrical parts: Schneider Electric

Hydraulic parts: Haimen Xinli

China: Anhui Wuyang

Oil pump: Shanghai

Seals: Japan NOK, Taiwan DZ

CNC system: snc52 (Nanjing Tianyuan), tp10s, CT8

Ball screw: Taiwan TBI

Servo motor: Nanjing

Product configuration

1. All steel structure design, production, beautiful appearance, reliable structure.

2. Using UG (finite element) analysis method, through computer-aided optimization design.

3. The whole steel plate welding structure, vibration aging to eliminate internal stress, so that the fuselage has good strength, stiffness and stability.

4. The left and right columns are welded with bottom plates to fix two oil cylinders. The left and right oil cylinders are arranged at both ends of the slider, and the slider is connected with the oil cylinder through the piston rod, which is driven up and down by the hydraulic system. The worktable is supported by arc cushion block and adjusting cushion plate, and fixed on the column with screws.

5. The frame is processed as a whole, rust is removed by sand blasting, and antirust paint is sprayed.

Performance characteristics

1. The slider adopts torsion shaft synchronous mechanism, and high-precision taper centering bearing (K-type) is installed at both ends of the torsion shaft, and eccentric adjustment mechanism is installed at the left end, so that the synchronous adjustment of the slider is convenient and reliable.

2. By using the deflection compensation mechanism of the upper die, a specific curve of the upper die can be obtained on the whole length of the machine through adjustment, so as to compensate the deflection of the worktable and the slider when the machine is loaded, and improve the bending accuracy of the workpiece.

3. In the angle adjustment, the servo motor drives the movement of the mechanical block in the oil cylinder, and the numerical value is displayed by the numerical control system.

4. Convenient lubrication device.

5. Vera workbench (optional)

Hydraulic system

1. The advanced integrated hydraulic system is adopted to reduce the pipeline installation and ensure the high reliability and safety of the machine tool in operation.

2. It can realize the speed of slider movement. Fast descent, slow bending, fast return action, and the speed of fast down and slow down can be adjusted properly.

Electric control system

1. Electrical components and materials meet international standards, safe and reliable, long life.

2. This machine is powered by three-phase four wire system of 50 Hz and 380 v. The motor of the machine adopts three-phase 380V, and the line lamp adopts single-phase 220V. The control transformer adopts two-phase 380V. Design of control transformer

The output is used by the control circuit, of which 24 V is used for the back stop control and the electromagnetic directional valve. 6V supply indicator light, and 24V supply other control elements.

3. The electric box of the machine is located on the right side of the machine, and is equipped with a door opening and power-off device. The operating elements of the machine are all concentrated on the CNC operating system except the foot switch, and the function of each operating element is marked by the image symbol above it. When the door of the electric box is opened, the power supply can be cut off automatically. In case of live maintenance, the micro switch pull rod can be pulled out by manual reset.

Nanjing Mavo Machine Tool Manufacturing Co., Ltd

Contact person: Wilson Wang / Danny Wu

Mobile phone: +8613276628018 / +8615722753754

Email:Wilson@mavomt.com / Danny@mavomt.com

Address: Dongshan Avenue, Economic development Zone , Jiangning District,Nanjing, Jiangsu Province,China